Mining, Minerals & Processing

Sutton has an expert team of industry professionals with multi-discipline & multi-commodity experience. Consulting to small and medium mining and mineral processing projects in Africa and globally where a need is identified.

We focus on small and medium sized projects in Africa and globally with specific focus on:

- Gold

- Silver

- Coal

- Tin

- Tantalum

- Tungsten

- Chrome

- Copper

Mining & Exploration Services

Sutton is active in natural resources exploration and mining. We have experience working with various commodities and have specific interest in Copper, Gold, Tin and Tantalum with ongoing projects in Ghana, Niger, Rwanda, Zambia and Zimbabwe.

Our approach combines highly skilled personnel with new technologies and techniques to provide turnkey solutions and mining support services including but not limited to;

- logistics

- procurement

- project management

- general mining and construction supplies

- supply and maintenance of earth moving fleet

Minerals Processing

Sutton is active in natural resources exploration and mining. We have experience working with various commodities and have specific interest in Copper, Gold, Tin and Tantalum with ongoing projects in Ghana, Niger, Rwanda, Zambia and Zimbabwe.

Our approach combines highly skilled personnel with new technologies and techniques to provide turnkey solutions and mining support services including but not limited to;

- logistics

- procurement

- project management

- general mining and construction supplies

- supply and maintenance of earth moving fleet

Process

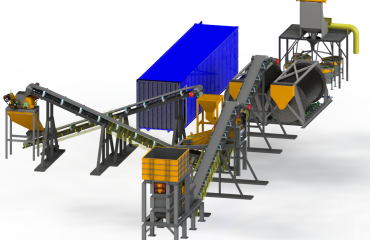

Sutton has a strategic investment in an OEM, ASG Processing Technologies engaged in the development, manufacturing, refinement and marketing of products and has been very successful in automation of gravity separation plants and creating mobile and small-scale solutions.

Sutton is committed to developing new technologies to assist the minerals processing sector.

- Our typical plants range from 3tph to 120tph.

Plug & Play Design Philosophy

We believe that small to medium scale mining projects are sensitive to many factors and paramount is cost and ease of commissioning and operation.

Central to our design and build philosophy is enabling the client to transport and erect an affordable plant in a remote location with maximum efficiency.

We ensure that every item from bolts, nuts and belts are shipped with the semi-deconstructed plant so as to achieve efficient commissioning.

Everything is then integrated into a Plug and Play system which is pre-assembled and tested.

Mobile Options

We have developed various trailer based, fully mobile plants capable of processing alluvial gold bearing or hard rock materials at 3tph by scrubbing and programmable automated concentrating.

The units can be towed by a pick-up truck with a 3t towing capacity.

Metals Recovery

We have developed small scale systems from 1tph – 20tph, and also supply medium scale systems from 20tph -50tph.

Design:

Our plant design features end-to-end design from feeders, conveyors, washing, crushing and concentrating.

Material crushing:

We integrate jaw crushers, impact crushers or mills as applicable in the process design.

Carbon in leach and carbon in pulp (CIL / CIP)

Using tested and proven systems we achieve better mixing and oxidization for CIP and CIL system with a much smaller footprint than conventional systems.

The systems are scaleable from 1.5tph to 50tph

Elution and electro-winning.

Our small scale elution and electro-winning systems are scalable, efficient, affordable and utilizes atmospheric ZADRA technology.